Mini PCs are valuable in industrial settings. Their compact size and robust features boost operations. They work well for remote monitoring and are energy-efficient with low power consumption. Easy integration and operational enhancement are key benefits. To learn more about compatibility, performance, connectivity, security, customization, cost-effectiveness, and future trends in applying Mini PCs to industry, explore further.

Key Takeaways

- Mini PCs are compact and energy-efficient, ideal for industrial settings.

- Compatibility with existing hardware and software is crucial for integration.

- Consider performance, durability, and ruggedness for industrial demands.

- Connectivity and security features are essential for industrial applications.

- Customization with industrial-grade components ensures reliability and operational efficiency.

Mini PCs in Industrial Environments

When deploying mini PCs in industrial environments, consider the ruggedness and reliability of the hardware to guarantee uninterrupted operation. Heat resistance is essential in industrial settings where temperature variations are common. Mini PCs with heat-resistant components guarantee stable performance even in extreme conditions. The compact design of mini PCs allows for easy integration into tight spaces often found in industrial setups, making them versatile and efficient solutions.

In addition to heat resistance, mini PCs should also be shockproof to withstand vibrations and mechanical shocks that can occur in industrial environments. This feature ensures that the system remains operational despite external disturbances. Remote monitoring capabilities further enhance the utility of mini PCs in industrial applications. This feature enables real-time monitoring of the system's performance, allowing for proactive maintenance and minimizing downtime.

Advantages of Mini PCs in Industry

In industrial settings, the compact size and robust features of mini PCs offer significant advantages for efficient and reliable operations. Mini PCs excel in providing solutions for remote monitoring applications in industrial environments. These systems can be strategically placed throughout a facility to gather data and monitor processes in real-time, enhancing overall operational visibility and control.

Moreover, mini PCs are designed with energy efficiency in mind. Their low power consumption not only contributes to cost savings but also reduces the environmental impact of industrial operations. By utilizing mini PCs, companies can optimize their energy usage without compromising on performance.

The compact nature of mini PCs makes them ideal for industrial applications where space is limited. Their small form factor allows for easy integration into existing machinery or control panels, enabling streamlined processes and maximizing workspace efficiency. Overall, the advantages of mini PCs in industry lie in their ability to facilitate remote monitoring, enhance energy efficiency, and optimize space utilization for improved operational effectiveness.

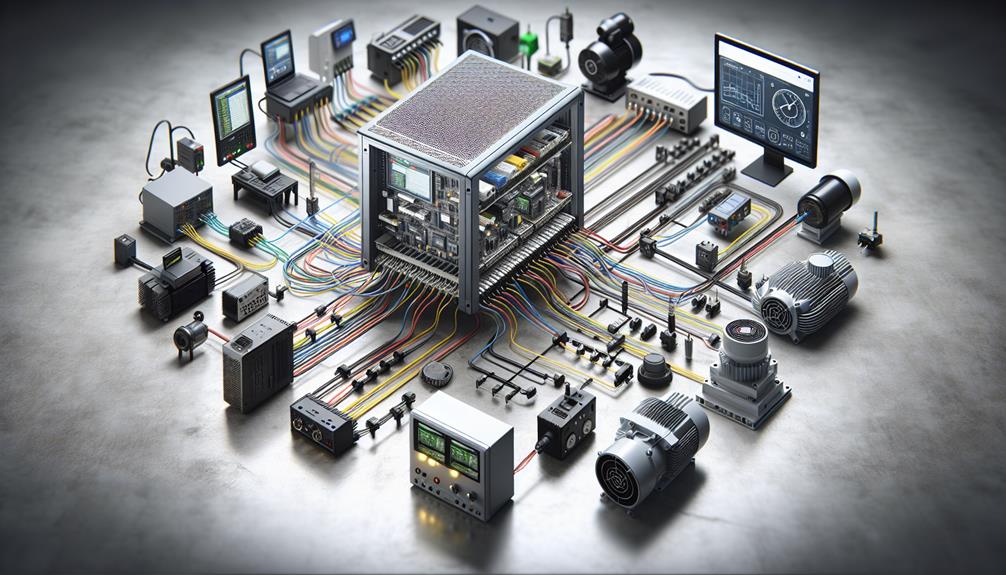

Challenges of Mini PC Integration

To effectively integrate mini PCs into industrial systems, careful consideration of compatibility with existing hardware and software is essential. Integration challenges often arise due to the specific hardware requirements of industrial settings. Mini PCs must be able to interface with various industrial sensors, actuators, and machinery, requiring specific input/output ports and communication protocols. Ensuring that the mini PC can connect seamlessly to existing industrial equipment is vital for successful integration.

Moreover, compatibility with industrial software applications poses another challenge. Industrial systems often run specialized software for monitoring, control, and data analysis. Mini PCs need to support these software applications, which may have specific operating system requirements or demand certain processing capabilities. Ensuring that the mini PC can run the necessary software efficiently is key to a smooth integration process.

Performance Considerations for Industrial Use

Considering the demanding nature of industrial environments, it is imperative to carefully evaluate the performance requirements when selecting a mini PC for industrial use. Two critical factors to take into account are power efficiency and heat dissipation. Industrial settings often require devices to operate for extended periods, making power efficiency essential to minimize energy consumption and running costs. Heat dissipation is also crucial as industrial environments can be harsh, with elevated temperatures impacting the performance and lifespan of components.

Moreover, compatibility and scalability play key roles in ensuring the mini PC can meet the evolving needs of industrial applications. Compatibility with existing industrial machinery, software, and peripherals is essential for seamless integration. Scalability is equally important to accommodate future upgrades or expansions without the need for significant investments in new hardware.

Connectivity Requirements for Industrial Applications

Efficient connectivity solutions are essential for ensuring seamless operations in industrial applications. When considering mini PCs for industrial use, it is important to assess their connectivity standards and compatibility with existing network infrastructure and protocols. Mini PCs must support various communication interfaces such as Ethernet, USB, Wi-Fi, Bluetooth, and serial ports to connect with sensors, controllers, and other industrial devices. Compatibility with industry-specific protocols like Modbus, Profinet, or EtherNet/IP is crucial for smooth integration into the industrial environment.

Network infrastructure plays a significant role in the performance of mini PCs in industrial applications. A stable and secure network with appropriate bandwidth is necessary to handle data transmissions effectively. Mini PCs should be equipped with Gigabit Ethernet ports for high-speed wired connections and support for the latest Wi-Fi standards for reliable wireless connectivity. Additionally, ensuring that the mini PC can adapt to different network configurations and security measures is important for safeguarding sensitive industrial data. By meeting these connectivity requirements, mini PCs can effectively support various industrial applications and processes.

Durability and Reliability of Mini PCs

For peak performance in industrial settings, guaranteeing the durability and reliability of mini PCs is paramount. Mini PCs designed for industrial use feature rugged designs that can withstand harsh conditions, ensuring an extended lifespan. These devices are built with environmental resistance in mind, capable of operating in a wide range of temperatures and humidity levels. Additionally, mini PCs engineered for industrial applications often come with shockproof construction, protecting internal components from vibrations and impacts that may occur in industrial environments.

The rugged design of industrial mini PCs goes beyond just physical durability. These devices are also engineered to resist dust, moisture, and other contaminants that could potentially compromise their performance. By incorporating shockproof construction, manufacturers guarantee that the internal components remain intact even in environments prone to vibrations or accidental drops.

Security Features for Industrial Settings

Industrial mini PCs necessitate resilient security features to protect sensitive data and guarantee operational integrity within high-risk environments. When it comes to security in industrial settings, remote monitoring capabilities play an important role. These mini PCs should offer secure remote access, allowing authorized personnel to monitor operations without compromising sensitive data. Additionally, robust data encryption is essential to safeguard critical information from unauthorized access or cyber threats. Data encryption ensures that all communication and stored data within the mini PC are secure and protected, even in potentially vulnerable industrial environments.

Customization Options for Industrial Needs

When customizing mini PCs for industrial needs, consider tailoring hardware specifications to meet specific operational requirements effectively. Customization flexibility is key in guaranteeing that the mini PC is equipped with the necessary components to withstand harsh industrial environments. Opt for rugged designs that can endure temperature variations, dust, and vibrations commonly found in industrial settings. Incorporating industrial-grade components such as solid-state drives, robust cooling systems, and durable casings enhances the mini PC's reliability.

Moreover, specialized software tailored to industrial applications is essential for seamless integration into existing systems. Make sure that the mini PC is compatible with the industrial software used in your facility to maximize productivity and efficiency. By customizing mini PCs with industrial needs in mind, you can create a solution that meets the specific demands of your operations. This approach not only increases the longevity of the mini PC but also enhances its performance in industrial environments.

Cost-Effectiveness of Mini PCs in Industry

Considering the total cost of ownership over the product lifecycle, mini PCs present a compelling cost-effective solution for various industrial applications. Energy efficiency is an essential aspect that contributes greatly to the cost-effectiveness of mini PCs. These devices are designed to operate using minimal power while delivering excellent performance, resulting in reduced energy consumption and lower operational costs. Additionally, the reliability of mini PCs guarantees minimal downtime, leading to increased productivity and cost savings in industrial settings.

Scalability is another key factor that enhances the cost-effectiveness of mini PCs in industrial applications. These devices offer the flexibility to scale computing power based on specific requirements, allowing businesses to adapt easily to changing needs without incurring additional expenses. Furthermore, the maintenance costs associated with mini PCs are relatively low compared to traditional industrial computers. With simplified maintenance procedures and fewer components to manage, mini PCs help reduce overall maintenance expenses, making them a cost-effective choice for industrial environments.

Future Trends in Industrial Mini PC Usage

For upcoming trends in the utilization of mini PCs in industry, a shift towards increased customization and specialized applications is becoming more prevalent. Emerging technologies are driving the demand for mini PCs that can handle advanced tasks with efficiency and reliability. Industries are increasingly looking towards mini PCs equipped with powerful processors, enhanced graphics capabilities, and expanded memory to meet their specific needs. These mini PCs are being tailored to operate in harsh environments, withstand extreme temperatures, and integrate seamlessly with existing industrial systems.

Moreover, the trend of remote monitoring is gaining momentum in industrial settings. Mini PCs are being utilized to collect real-time data from machinery, sensors, and other equipment, allowing for predictive maintenance and proactive troubleshooting. The ability to remotely monitor and manage industrial processes through mini PCs enhances operational efficiency, reduces downtime, and minimizes maintenance costs. As industries continue to embrace digital transformation, the adoption of mini PCs for remote monitoring is expected to grow, enabling smarter and more streamlined industrial operations.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.